Isn’t that a heat sink?

Isn’t that a heat sink?

Ah, OK. You’re not using it for it’s intended purpose as constructed.

Now I get it. Good luck with the project!

Do you mean will the primary coil draw current if plugged in?

Yes.

Not to be critical, but it’s a weird question. It’s not a bad question, I just can’t figure out what you’re attempting to do by removing the motor? And, why you’d keep it energized if you remove the motor?

Car horns are usually ground switched.

There’s no resistor in a standard 12v relay (other than the coil itself).

This should work with no issues, provided your car has a typical horn circuit.

Check a wiring diagram for the car. Cars used to run the horn circuit through the horn switch on the wheel directly, no relays or anything else - the power for the horn went through the horn switch (well , the ground side anyway, which still has to support the horn current load).

Automotive relays generally take very little current to operate (like 0.5 amp) - it’s kind of their function to switch a high-load circuit using a low-current circuit.

I can’t splice into the wire coming out of the switch to detect when the horn is pressed, since it’s a shared ground with other components.

This doesn’t add up. If it’s a shared ground that’s switched, then other things wouldn’t work if the horn switch wasn’t engaged.

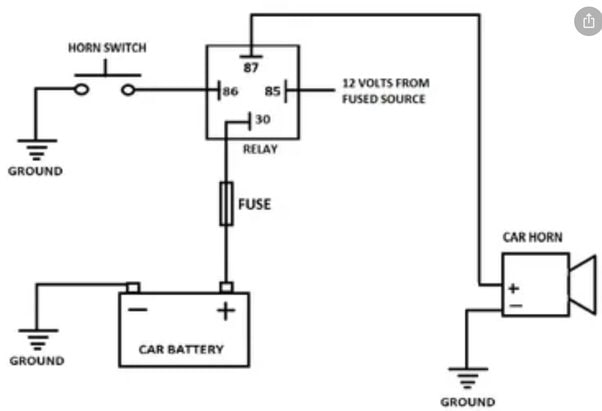

This is a typical horn wiring.

You’d want to wire your relay the same as the horn relay (ground switched, tapped into the wire between the horn switch and relay), or use #87 as your trigger into your relay’s #30 (wiring your relay as positive switched, typical config), or even more easily, just wire your actual device to #87, as horn circuits generally have moderate current capability (the wires are often 14 gauge).

Wow, what a great comprehensive response. Thanks for the links.

I’ll be saving this. Brilliant stuff.

Wow, pretty fascinating stuff.

Interesting.